ADVANTAGES

* We, at Sanskar Agro use high qualities of MCU5 and Shankar6 cotton, known for their superiority in terms of fineness and good feel.

* Directly from Farmers

* Containmation clearer in Ginning Factory to remove impurities in cotton

* Located in Highly rich cotton belt in Maharashtra region

* Has self sufficient HVI testing laboratory

* Clean fibre and more yarn realisation

* Ginning in TMC (Technology Mission of Cotton) approved factories under special supervision.

* Optimum moisture level of 7.25% maintained and water contamination due to excessive moisture avoided.

* Various measures are taken to avoid contamination.

* Workers remove visible contaminats by hand picking.

* Best Selected Lint with low Short fibers content

* Highest Yarn Realisation more than 76% in case of Combed Yarn (against standard 68% while using non Sanskar Cotton from India)

* Bale Management offered at nominal extra cost

* New safe packing with modern automatic baling.

COTTON PARAMETERS

Test Parameters Of Main Indian Cotton Varieties (in HVI Mode)

| Type | Length (mm) | Mic. | Strength (GPT) | Trash (%) |

|---|---|---|---|---|

| S-6 | 27.5 - 29 | 3.5 - 4.1 | 28 - 29 | 2 - 3 |

| MCU-5 | 30 - 32 | 3.8 - 4.35 | 29 - 32 | 2 - 3 |

We can offer raw cotton ginned in our fully automized unit in full pressed bales weighing 170 kgs per bale covered with cotton cloth.

QUALITY

SANSKAR AGRO PROCESSORS PVT LTD, is a Cotton Ginning & Pressing TMC unit (Technology Mission of Cotton) approved factories to ensure better uniformity, controlled contamination and quality grade fibre.

Quality

* Kapas is hand picked, fibre is not damaged

* Expert selector at factory to buy cotton directly from farmers

* No human handling is done of the kapas while transferring it to the ginning machine, directly through cotton loaders

* Kapas and the final cotton is all kept on cemented floor

* Moisture is controlled at every stage.

* Only cloth brooms are used for cleaning.

* Kapas and final cotton is kept on cemented floor and not on mud / dust.

* The cotton bales are packed in cotton cloth - NO PLASTIC OR JUTE MATERIAL IS USED FOR THE SAME.

COTTON WASTE

Comber Noil

All waste is collected by pneumatic waste collection system and transferred to Automatic bailing system and converted into Fully pressed bales of 170 Kgs. All bales are properly covered with cotton cloth.

Quality Parameters Of Noil

We are producing finest quality yarn that matches with USTER 5% LEVEL. It is mainly due to best variety of cotton we use. No doubt we are taking special care of contamination during selection of cotton. The parametres in Comber Noil are as under :

| 2.5% SL | 19.50 |

| 50% SL | 8.20 |

| UR% | 44.34 |

| SFI | 24.55 |

| MIC | 3.35 + |

| TRASH % | 0.28 |

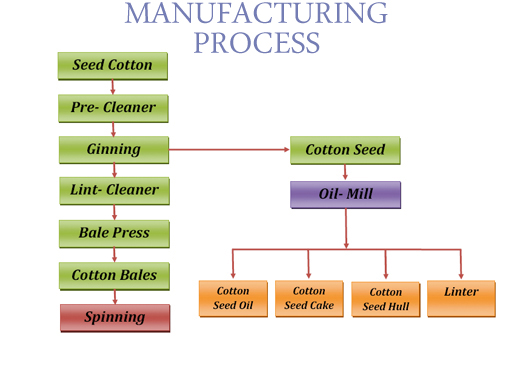

Cotton Seeds

We are having our Own Oil mill unit wherein the cotton seeds are crushed and Cotton seed cake is manufactured.